UV Varnish

Our UV varnish offers permanent protection to your most exposed plastic parts.

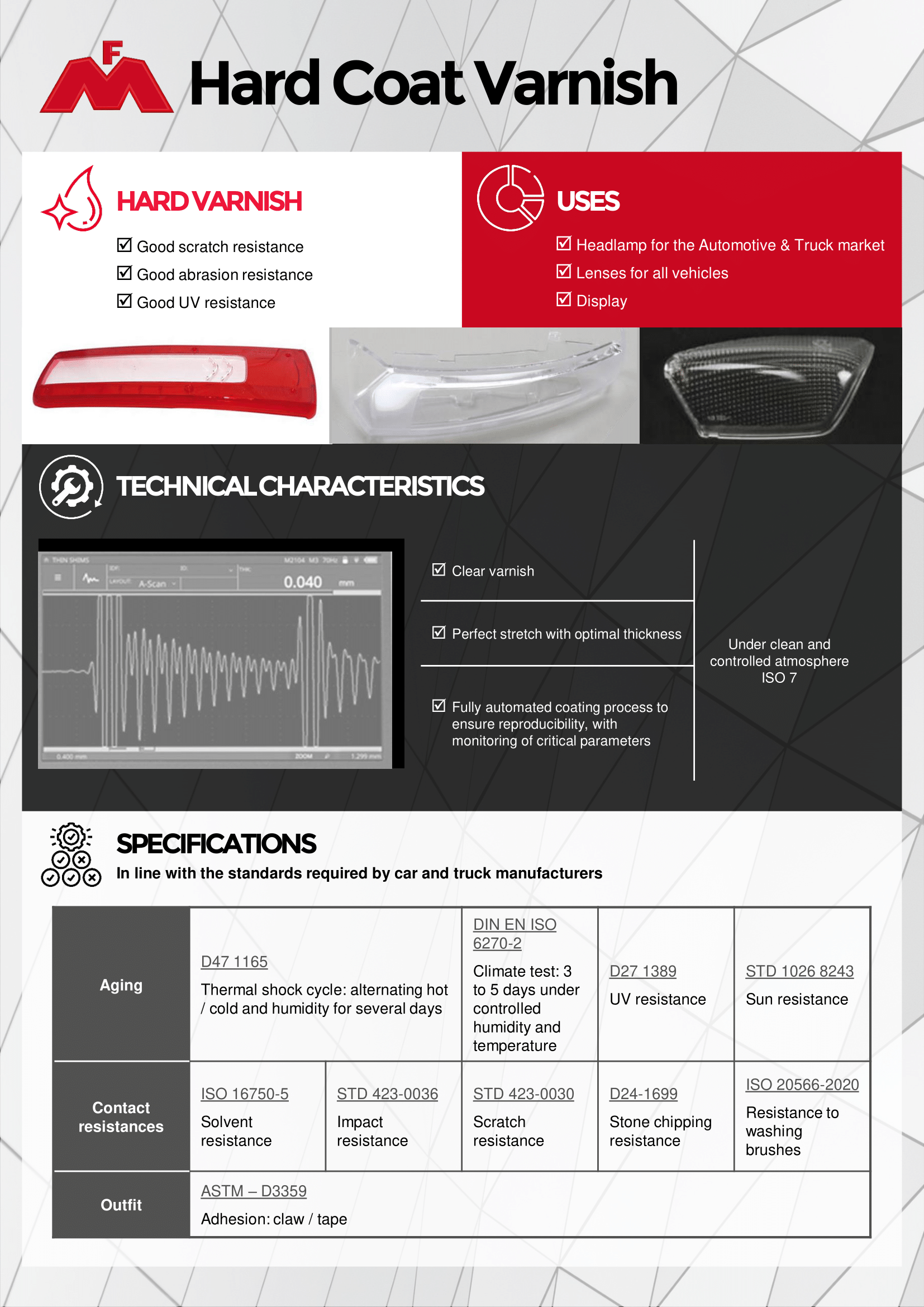

Hard Coat Marmillon varnish: optimal protection for your plastic parts

Marmillon Hard Coat varnish – or Vernis Dur in French – is an ideal solution for protecting plastic parts from external aggressions.

The varnish improves the resistance of parts to scratches, abrasion and UV rays. It is commonly used in the automotive industry for appearance parts in direct contact with an external environment.

Spray technology with UV reticulation

UV spray technology is the most widespread for producing exterior lighting parts, particularly for car headlights on the Headlamp market.

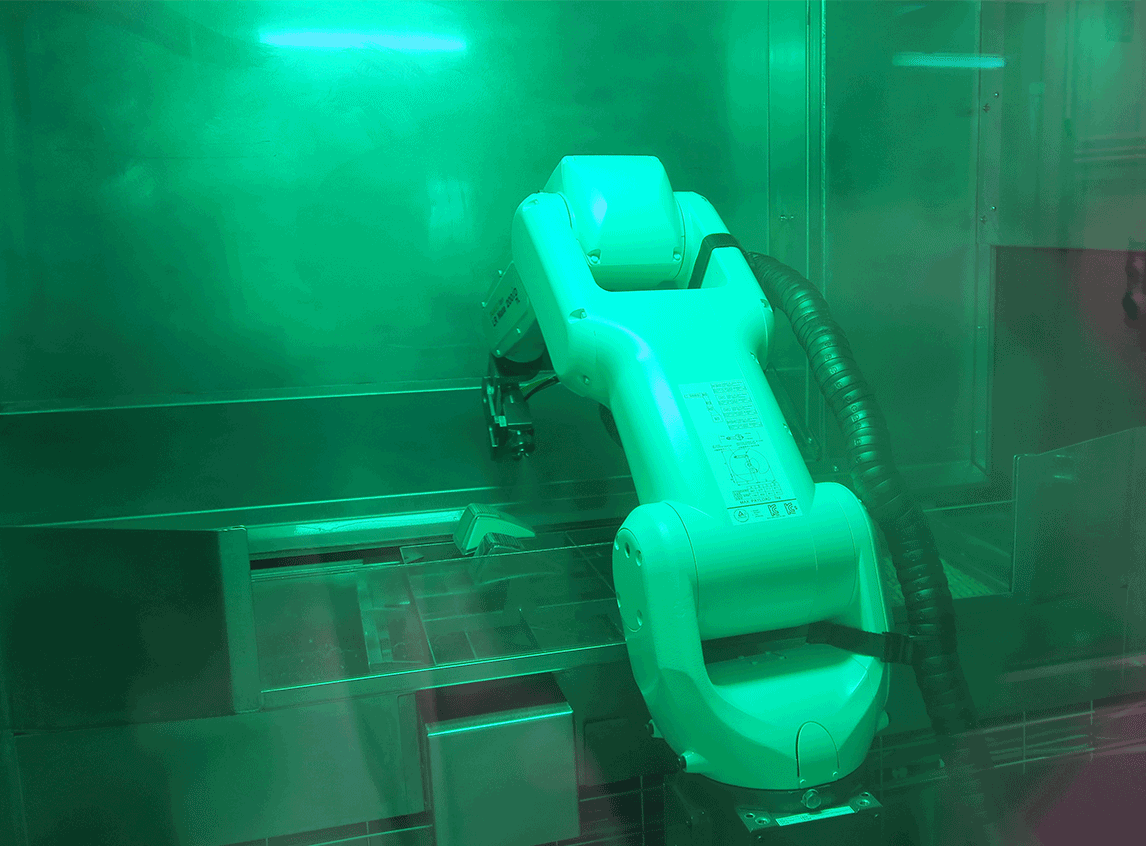

The process

- A thin layer of varnish is deposited by spray using a 6-axis robot

- The crosslinking of the varnish is obtained by exposure with UV lamps

- The glaze becomes instantly hard, without the need for longer baking

- The plastic part then has its final resistance characteristics

Mastery and Quality

Marmillon’s fully automated varnishing line guarantees optimal quality thanks to:

- quality standards

- specific programs per room

- monitoring and recording of critical parameters

- alarms in the event of a malfunction

- an ISO 7 cleanliness level

Specific dimensions

Dimensions of Marmillon varnished parts:

- maximum width and length of 450 mm

- maximum height of 120 mm

Technical application: Vacuum metallization and Hard Coat varnish

An R&D project is underway to varnish metallized products directly manufactured at Marmillon.

This technical application will ultimately make it possible to offer products as a substitute for chrome products. An alternative solution that will be increasingly demanded due to its environmental benefits. It must meet the strictest requirements in terms of exterior parts for vehicles.

Technical sheet for Marmillon Hard Coat Varnish

France Relance: Marmillon winning company

Aid from France Relance enabled the group to acquire a new varnishing line, thus constituting an investment opportunity and a growth accelerator. This varnish production line was essential to the launch of new products and the group’s expansion into new markets.